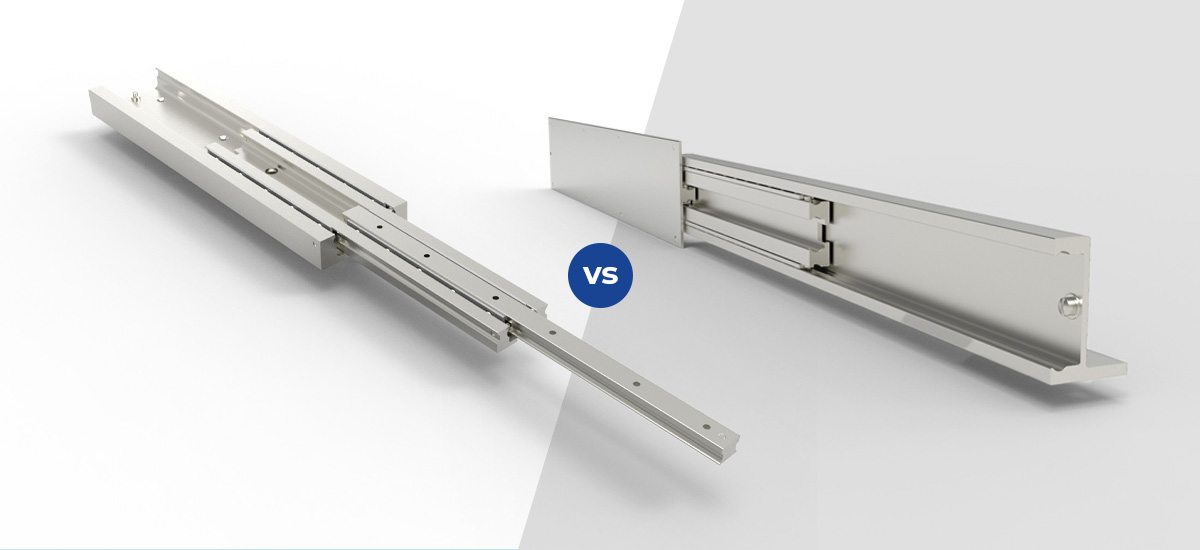

Heavy-Duty vs. Standard Drawer Slides

Heavy-Duty vs. Standard Drawer Slides

Choosing the right type of drawer slide can impact your assembly, cost targets, and intended application operation. These components allow for seamless movement when you open and close a drawer. They reduce friction so the drawers can extend to their full capability with minimal effort and ability to support its intended load carry. With many types of drawer slides available, it’s typical to make decisions of slide rail selection.

Choices include:

- Application load to be carried is about the same as catalog load ratings, consider another slide series with greater load rating

- An estimated number of cycles the application will experience in yearly or lifetime.

- If possible, select slide with the maximum slide length and most minimum slide travel to meet application.

- If low number of cycles are expected, a pair of slide rails can exceed catalog load ratings

Drawer slides are based on 3 general load rating terms. All slide manufacturers have different criteria to illustrate what their products are expected to carry. Some slide manufactures use various terminologies to present their products. Terms:

Light Duty – generally 100 pounds / 45 kilograms or less

Medium Duty – range from 100 pounds / 45 kilograms to 250 pounds / 113 kilograms

Heavy Duty – greater than 250 pounds / 113 kilograms

Load ratings expressed in a “linear format” – shorter lengths carry more load, longer lengths carry less load. Load ratings expressed in single slide length, mounted onto single drawer width, single number of cycles in & out. No other information is available for other slide lengths or travels. Load ratings based on class of ratings – grouping of single values per product line. Example: 50 Pound / 23 kilograms Class, 100 Pound / 45 kilograms Class, 150 Pound / 68 kilograms Class, and so forth. No exact load value is assigned to specific slide length or travel. Load ratings based on ultimate load support at maximum with no number of cycles referenced. Example: slide pair at ultimate load but before failure without consideration to number of cycles, load center of gravity, or drawer width.

What Are Standard Drawer Slides?

Standard Drawer Slides are considered to be illustrated within a manufacturer’s catalog or are available as off-the-shelf part numbers, without any modifications.

Special Drawer Slides are available to the exact specifications required by a customer. Special Drawer Slides may have modifications to meet final application requirements.

Typical modifications include:

- Change to slide extension / travel as either greater or less than catalog slide

- Change to mounting screw hole sizes

- Change to mounting hole locations

- Adding of multiple locks

- Adding lock closed feature

- Adding detent closed or open not available from specific catalog part numbers

- Adding pre-assembled Adapter Brackets, set to specific dimensions

- Changing or part number marking, or packaging, of number of slides per carton

- Changing of finish to meet environmental requirements

- Special construction to meet load carry or overload requirements

Frictionless operation: Most slides are fabricated with a “pull force measure” to meet a wide range of applications.

Weight capacity: Generally noted as “Pair”. Some slide series are indicated as “Each”. Working Load is the amount of load of the installed application with a reasonable amount for cycles. Most slides have 2X Static Load at fully open position. Typical is also an 5X applied load when the application is in the closed position.

Extension options: Standard slides provide a choice in how you want the drawer to extend. Some possibilities include partial or full extension or overtravel or under-travel to control your drawer access out of stationary structure.

Versatility: Slides are installed and utilized in almost every application possible. Low number of opening or closing the unit from stationary structure. From initial mounting slides to application, no further movement is done. High number of cycles for an application, Cash Drawer applications may include 4 million continuous cycles in its lifetime.

Ease of use: All products are designed to function in a linear motion from full closed to fully open positions and back to the closed position.

Affordability: Pricing is based on specific Market the final application participates in. Pricing is based on Quantity to be ordered. Pricing is based on either as a separate charge for Tooling (if needed) or if Tooling is to be amortized into part cost or quoted as a separate charge. Carbon Steel Slides are generally less than Stainless Steel Slides and are less than Aluminum Slides depending on specific part number ordered.

What Are Heavy-Duty Drawer Slides?

Heavy-duty telescopic slides are designed to withstand challenging conditions, larger loads, shock and vibration concerns. They’re common in industrial and commercial settings where additional strength is essential. Heavy-duty slides are engineered to support considerable loads while providing smooth and reliable operation in various settings.

Heavy-duty slides offer several advantages in the right environment, making them ideal for applications like tool storage units, filing cabinets, truck slide out trays, and heavy industrial equipment. Many types are available, but side mount and undermount are common for rugged applications. Manufacturers use hardy materials and robust construction methods to enhance their durability, extending the life of the slides and heavy-duty linear rail guides.

Some of the features of heavy-duty slides include:

- Durable construction: Heavy-duty slides generally require construction and materials to handle physical loads, unexpected over-loads, shock and vibration, or other factors depending on final application.

- Weight capacity: These slides must handle heavier loads, from 150 to over 500 pounds per pair.

- Engineered design: Jonathan Engineered Solutions provide load ratings based upon individual market requirements.

- Example:

- Defense Market – typically low number of cycles in its lifetime

- Industrial Market – typically 10,000 continuous cycles

- Electronic Market – generally 1,000 or less continuous cycles

- Aerospace Market – per customer requirements

- Shock and Vibration – added components inside of slides to handle requirements to meet customer / or market specifications

- Military Specifications

- Customer Specific Specifications

- Example:

- Full extension: Many heavy-duty options have full extension capabilities, maximizing the usable space for industrial and commercial applications.

- Stability and safety: These slides carry the Working Load, Static Overload in full open position, and Static Overload when application is fully closed

What is the Difference Between Light Duty and Medium Duty and Heavy-Duty Drawer Slides?

Load Rating is the main difference between the three categories. When in doubt that the application load is at the maximum catalog load rating, consider the selection of next level of load grouping.

The three general categories are:

Light Duty – generally 100 pounds / 45 kilograms or less

Medium Duty – range from 100 pounds / 45 kilograms to 250 pounds / 113 kilograms

Heavy Duty – greater than 250 pounds / 113 kilograms

Durability is the principal difference between three groups. When you compare them, visible differences exist in their size. As the categories change, the physical slide thickness and height will change, as the load ratings increase. While these features make them more reliable, they often require more space considerations between the stationary mounted slide and the moving drawer, which can be limited in small spaces or if you need a more compact design.

Some other differences between these slide types are their weight capacity and length. Heavy-duty options can carry larger loads, and you can also find them in lengths of 10 inches / 254 millimeters through 60 inches / 1524 millimeters. Both Light Duty and Medium Duty slide lengths are available from 10 inches / 254 millimeters through 30 inches / 762 millimeters.

CAUTION:

There are differences in slide lengths, depending on manufacturer. Some manufacturers will list the slide lengths in “inches” where other companies list slide lengths in “millimeters” based on 50mm increments and the part number will indicate assumption of inches but is actually a lesser length.

Example:

Jonathan Engineered Solutions part number will indicate Series – Slide Length. In this case the model is number 370-18 (370 Series dash 18-inch Slide Length)

Other slide manufacturers will use Series – 18 (Series dash 457 millimeters) and actual slide length is 17.71 inches / 450 millimeters.

Reference Chart –

| Nominal Inches | Millimeters | Actual Slide Length Inches |

| 10 | 250 | 9.84 |

| 12 | 300 | 11.81 |

| 14 | 350 | 13.77 |

| 16 | 400 | 15.74 |

| 18 | 450 | 17.71 |

| 20 | 500 | 19.68 |

| 22 | 550 | 21.65 |

| 24 | 600 | 23.62 |

| 26 | 650 | 25.59 |

| 28 | 700 | 27.55 |

| 30 | 750 | 29.52 |

Do You Need Heavy-Duty Slides?

As they require a more significant investment, knowing when to use heavy-duty slides is essential. Consider the following factors:

Weight Requirements

Consider what you plan to store in the drawers and how much those items weigh to determine the maximum load capacity you need. Also consider if an unanticipated momentary overload or rough usage (slamming drawer closed or unexpected lateral applied load). If the items weigh over 250 pounds / 113 kilograms, look for heavy-duty slides to avoid unnecessary damage or breakage.

Available Space

Your drawers and slides must fit in the available space. If you opt for heavy-duty slides, you must account for the additional space they occupy between the stationary structure and moving item.

Length and Extension

Heavy-duty applications often require drawer slides with additional length and extension. Heavy-duty telescopic slides allow for moving heavy loads, making them ideal for various applications.

Frequency of Use

Heavy-duty drawer slides are preferable if your application requires frequent opening and closing of the drawers, as they can withstand a busy commercial setting.

Additional Features

Decide whether you need any available features, like locking capabilities or alternate materials.

Stability

While slides are installed and utilized in a wide range of applications, heavy-duty slides will move increased loads with minimum effort to pull unit outward or retract inward.

Operating Environment

Humidity, temperature and debris affect drawer slide durability and performance. If you operate in a hot, humid or outdoor environment, choose heavy-duty slides with corrosion-resistant materials to boost component longevity.

Materials

Drawer slide materials determine their load capacity and suitability for your applications. Typical materials to consider when choosing a drawer slide include:

- Aluminum: High-quality aluminum is a common material for heavy-duty slides. It’s lightweight, durable and corrosion resistant. Ideal for many defense, aerospace, and industrial applications.

- Steel: Steel is an ideal material for slides. It’s common in indoor installations.

- Stainless steel: This durable and corrosion-resistant material is suitable for drawers installed outdoors, in refrigerators / freezers, or other challenging conditions.

Contact Jonathan Engineered Solutions for All Your Linear Motion Needs

The right drawer slides can boost your operation’s efficiency and save money. If they’re suited to the application, drawer slides last longer, meaning fewer repairs and replacements. Whichever type of drawer slide you choose, you need a supplier you can trust. Jonathan Engineered Solutions is a certified fastener provider for aerospace, defense and industrial applications. We offer precision ball bearing slides for standard and heavy-duty applications, brackets, cable management systems and more.

Our commitment to excellence in motion means exceptional customer service. As a JES client, you’ll work with an assigned expert to handle all of your account requirements. Reach out to us for reliable and durable custom engineering solutions today!

Speak with a Sales Representative

Our representatives have a wealth of knowledge on all our products – let them steer you in the right direction.

Learn More