What Are Telescopic Drawer Slides?

Drawer slides are critical attachments to equipment as a means for mounting drawers, electronic chassis, trays, within a stationary structure or as a functional device to bring same equipment outward for maintenance, repair, or interchanging out of / into a fixed cabinet. The selection of slides ensure your drawers are smooth and operational, limiting noise and boosting longevity even in challenging conditions. In contrast, choosing the wrong slides can impact your equipment usability or even collapse under the weight of actual load or unanticipated over-load.

With many types of slides available for different applications, selecting the right option for you can be challenging. The more you know about telescopic slides, the better you can make a decision that suits your unique industry and business requirements.

What Are Drawer Slides?

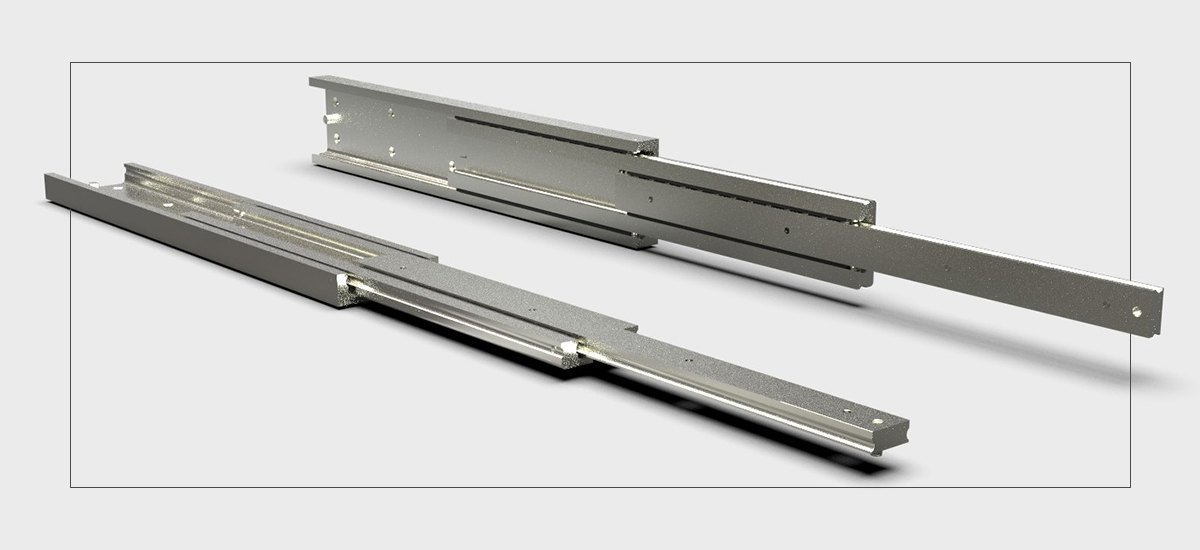

Telescopic slides allow equipment to slide in and out in a smooth, linear motion. As the name suggests, they consist of multiple sections (2-section, 3-section, 4-section) that slide within each other, expanding and retracting like a telescope. When you pull a drawer equipped with telescopic slides, the interlocking sections extend, allowing the drawer to open and providing maximum accessibility required by the application intended.

Most telescopic slides use simple components. They also support the weight of the drawer box and reduce friction as you slide the drawer in and out of the stationary structure. A drawer box operating without a telescopic slide would create constant friction as it moved against the housing, making installation or removal of the drawer difficult.

Types of Telescopic Slides

Telescopic slides come in several varieties to suit different drawer functions and weights, including:

- Ball-bearing telescopic slides: These slides feature bearings on the cabinet and drawer components. They offer effortless operation and significant reliability and durability, making them ideal for heavy-traffic areas such as office workstations and filing cabinets, military and commercial electronic chassis, industrial storage, aerospace interiors, and vehicles such as fire trucks or work trucks.

- Friction slides: These solid-bearing slides (no ball bearings or rollers) feature interchangeable inner members. They’re cost-effective, easy to install and suitable for different installations. They also allow for total extension, making them ideal for rugged applications like military and aerospace.

- Roller slides: These slides provide an alternative to ball-bearing or friction slides. They consist of stationery and moving members, equipped with carbon steel or stainless steel rollers. These rollers rotate while the slide is operated outward or inward to facilitate smooth movement and load carry ability. Roller slides are also offered when equipment is extended outward with the additional function to rotate the equipment up or down.

- Side-mount telescopic slides: Side-mount slides are mounted vertically on the cabinet member and the drawer member. They offer a traditional, versatile and cost-effective mounting option, making them ideal for many wide-ranging applications.

- Center-bottom mount telescopic slides: Center-mount slides consist of a single slide mounted at the bottom center of a drawer. They’re mounted from the back to the front of the drawer, making them best suited to small, light-capacity drawers.

- Bottom-mount telescopic slides: 2 types of mounting using a pair of slides in a flat orientation below the bottom of sliding unit or a pair of slides, mounted vertically but below the bottom of the sliding unit.

- Full-extension telescopic slides: These slides will travel outward 100% or greater of their length, giving you complete access to the drawer’s contents. They withstand high use, making them suited to applications requiring maximum storage space and quick access to the drawer’s contents.

- Three-quarter extension telescopic slides: Three-quarter travel slides allow the drawer to open up to 75% of its entire length. They’re ideal for small spaces and are common with side mounting or center-mount slide styles.

- Two Way Travel telescopic slides: Based on only 2 slide members, stationary and moving, the slide will travel from a mid-position to move either left or right. Depending on orientation, the slide from center position move outward or rearward, returning slide to its closed centered position.

- Locking telescopic slides: These slides prevent drawers from opening or closing accidentally. They’re ideal for transportation applications, such as recreational vehicles, electronic chassis, or fire trucks, as they ensure the drawer remains closed while the vehicle moves.

- Push-to-open telescopic slides: These telescopic slides are ideal for applications with limited space. They fit with a spring mechanism that enables the user to eject the drawer open when they push it rearward slightly.

- Soft-close telescopic slides: As the name suggests, soft-close slides have a damping mechanism to prevent the drawers from slamming when closed. They’re ideal for keeping drawer contents in place, making them a popular choice for aerospace, furniture, and defense electronics.

The Benefits of Telescopic Drawer Slides

Telescopic slides offer significant benefits for a range of applications, including:

- Space optimization: Telescopic slides allow you to fully extend drawers out of a stationary structure, making accessing items at the back of the drawer easier. As you can access stored items quickly, you can make the most of your storage when you have limited space, making them ideal for applications that prioritize organization.

- Smooth operation: The function of telescopic drawer slides allows them to slide open and close with adequate load carry and overload conditions, making them easy to operate in various environments.

- Versatility: Telescopic slides have many applications, making them a favorite in aerospace, defense, industrial, electronics, and vehicle designs. They also boast many customization options for your unique needs.

- Durability and longevity: As telescopic ball bearing or roller slides, their construction allows reduced friction, and many are suitable for challenging applications. Their durability makes them cost-effective in the long term as you spend less time on repairs and replacements.

- Length and extension: Drawer slides come in many different extension options.

- Partial Extension – based on a 2-member slide, the travel extension is 75% of the slide closed position / collapsed length

- Full Extension – based on 3-member slide, the travel extends 100% of the slide closed position / collapsed length

- Two Way Partial Extension – based on a 2-member slide, the moving motion is partial travel left or right

- Linear Motion – based on a 2-member slide, the moving slide member is contained within the slide length. Travel is within the overall slide length.

- Pivot Motion – based on a 3-member slide, the moving member at its full extended position may be rotated upward or downward.

Factors to Consider When Choosing Telescopic Drawer Slides

Choosing the right telescopic slide for your application is critical. Considering the following features can help you narrow down your options:

Load Capacity

One of the most important considerations is ensuring your chosen telescopic slides can carry the intended load. For example, catalog off the shelf standard slides, can hold weights of up to 500 pounds per pair, while custom constructed slides have potential to hold 1500 pounds per pair of slides.

Material and Finish

Slide material has an effect on its load capacity and is suitable depending on the intended applications. These include:

- Aluminum – for load rating per catalog, use of 6061alloy will improve by selecting 7075 alloy. Additional change to improve load carry, is using aluminum slide with “hard anodize” finish.

- Carbon Steel – for environmental concerns, normal finish zinc with clear chromate can be replaced by using zinc with yellow chromate.

- Stainless Steel – common slide material. Improved load rating can be applied over carbon steel. Environment the slide application will be installed is to be considered as stainless steel is corrosion resistant and load carry is greater than carbon steel..

Mounting and Installation

Consider how you want your slides to operate and ensure you choose a mounting option Side mount / Hard Mount, Undermount, use of Adapter Brackets — that suits the cabinet’s design and application.

- Side Mounted Hard Mount– consideration of stationary structure clear opening with dimension and assigned tolerances will combine with overall width of unit being installed, to allow correct slide to be selected.

- Undermount – unit to be installed, its width is not considered. Space below unit to be installed, slide thickness without added tolerances can be considered.

- Adapter Brackets – cabinet clear opening width and tolerances to be considered. Chassis width tolerances to be considered initially. Once the nominal available space is considered, the use of Adapter Brackets allows dimensional differences to be realized.

Experience Excellence in Motion With Jonathan Engineered Solutions

The right high-quality telescopic drawer slides can streamline your operations and ensure you can trust your equipment. At Jonathan Engineered Solutions, we specialize in linear slide solutions that meet your needs, regardless of your industry or application. As a certified AS9100 and ISO 9001 manufacturer of linear slides with over 60 years of experience, you can trust us to deliver standard catalog or modified custom solutions that meet your industry’s highest performance standards.

Contact us online today and an experienced team member will take you through the best options for your application and help you pick the ideal telescopic slides, brackets, cable management carriers, trays, or accessories

Speak with a Sales Representative

Our representatives have a wealth of knowledge on all our products – let them steer you in the right direction.

Learn More