Services

Your Single-Source Supplier for Linear Movement Solutions

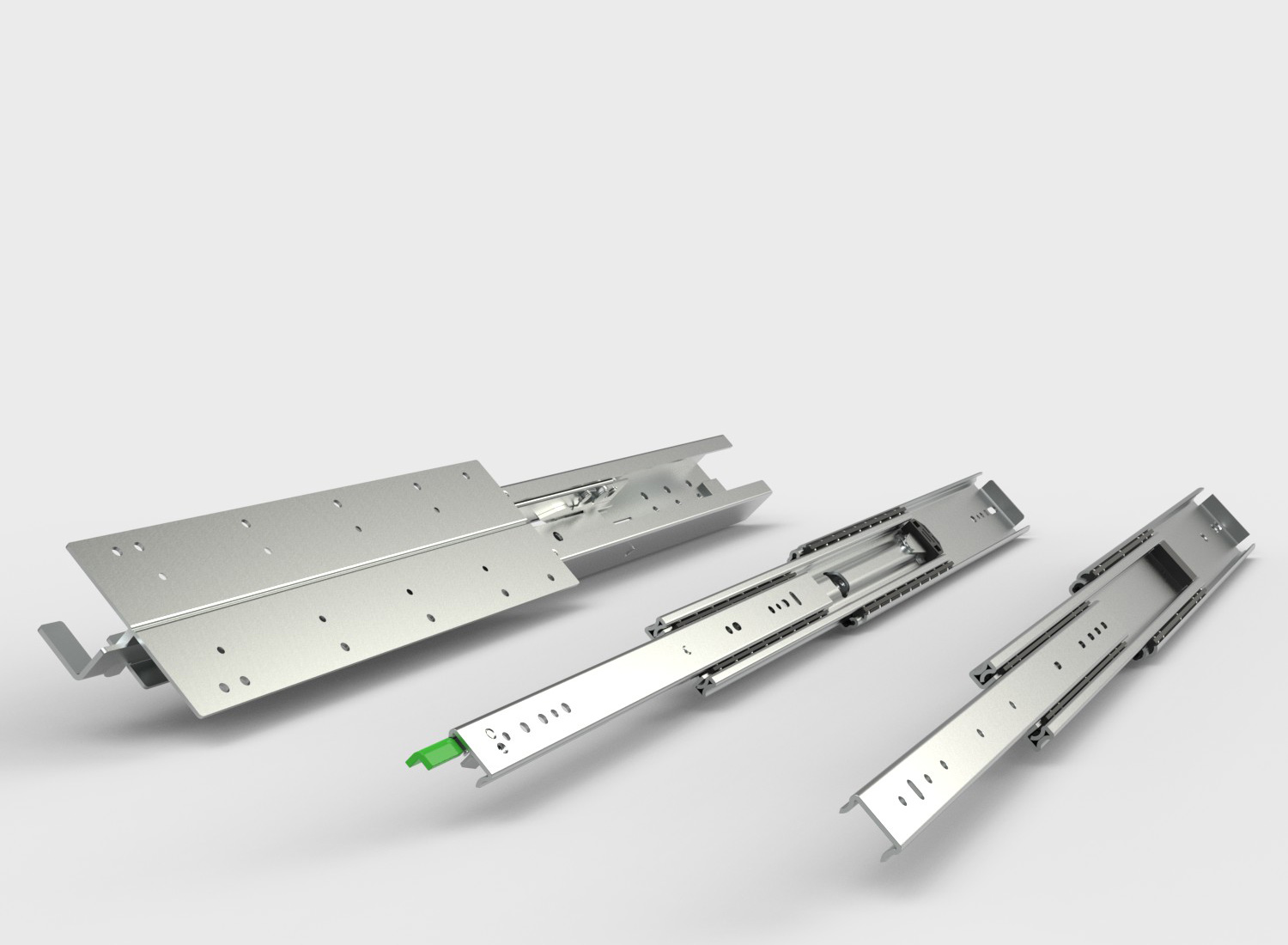

You're not limited to furniture slides or standard hardware from Big Box stores that require you to alter your applications to accommodate the hardware. Jonathan Engineered Solutions can provide you with a custom product or assembly with no minimums and unique part numbers for tracking, quality, and replenishment. Jonathan can absorb your ancillary machining or sheet metal work to help complete your application and reduce your supplier base. Relying on Jonathan's experience and manufacturing capabilities can streamline your projects for more rapid technology insertion and field deployment.

COTS & Modified Solutions

We have conquered the complex learning curve of managing engineered sourcing and have over 60 years of experience in sourcing industrial/OEM products, components, and assemblies. Engineered components and assemblies are certified with quality, inspection, first article reports and provide you with competitive engineering sourcing solutions from start to finish.

-

- Cost savings for profitability and price competitiveness

- Increased efficiency and productivity of expanded peripheral products, components, and assemblies.

- Certified quality, technology and production inspection

- Complete integration and assembly of your product solution.

- Delivery of your quality product on-time or hold products in inventory

99%

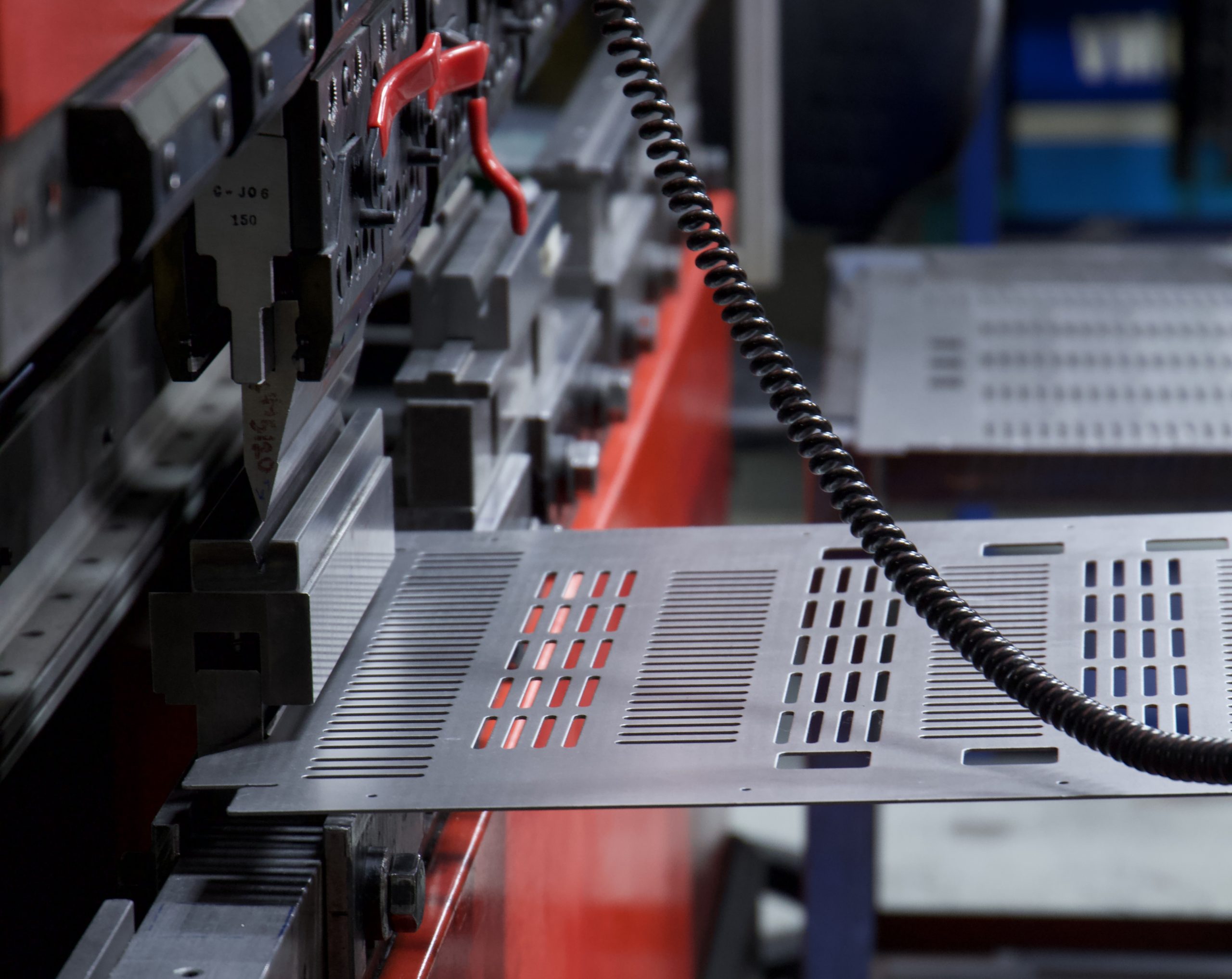

Vertical Integration

Jonathan Engineered Solutions is capable of taking your required inputs to design, prototype, test, and run production on your unique part number all within the walls of our facilities.

OUR PRODUCTS

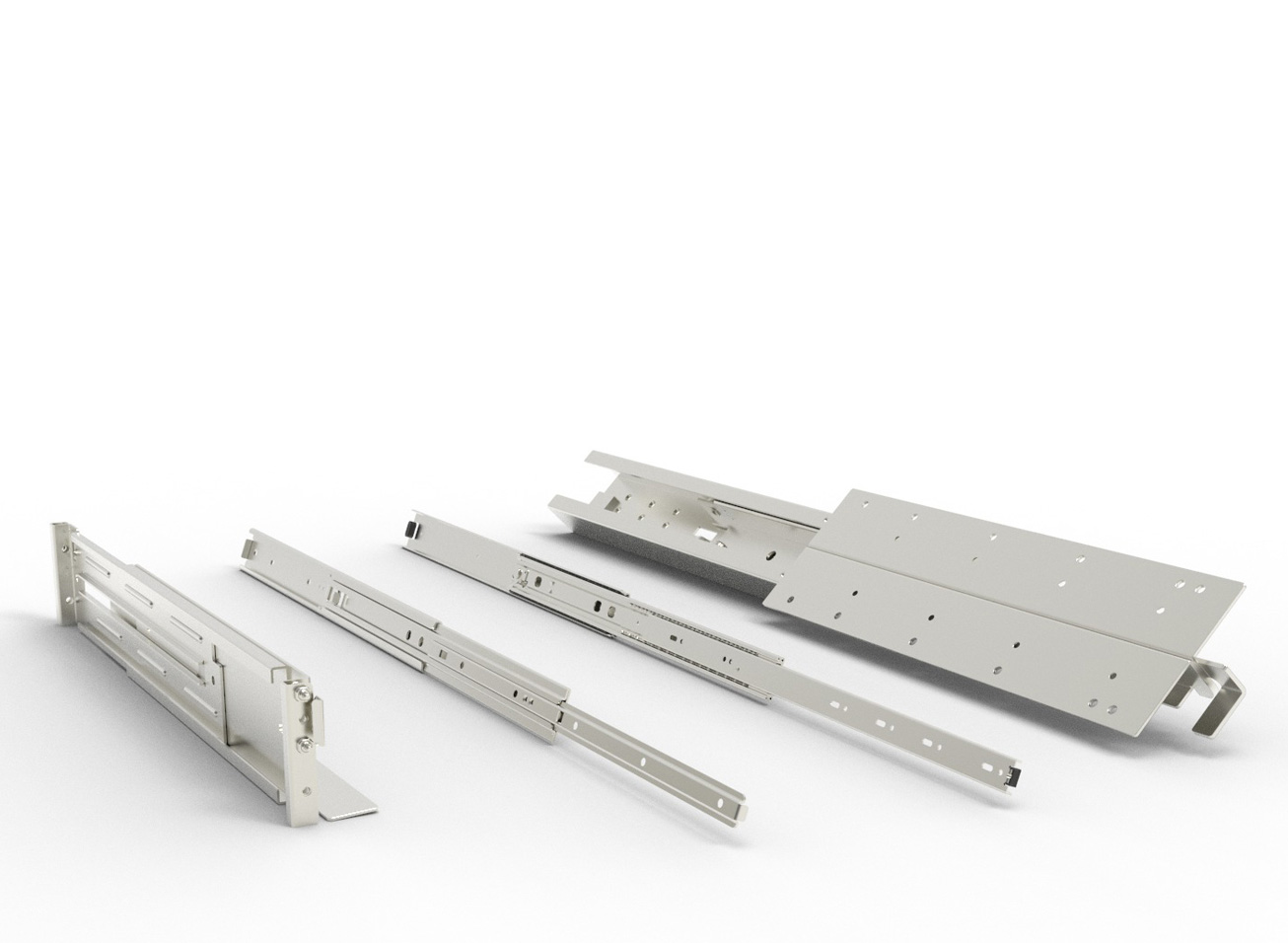

All Jonathan products and kits can be tailored for every application or specific requirement. When you need low volume, highly customized linear motion or rack-mounting solutions, we're ready to take your call.

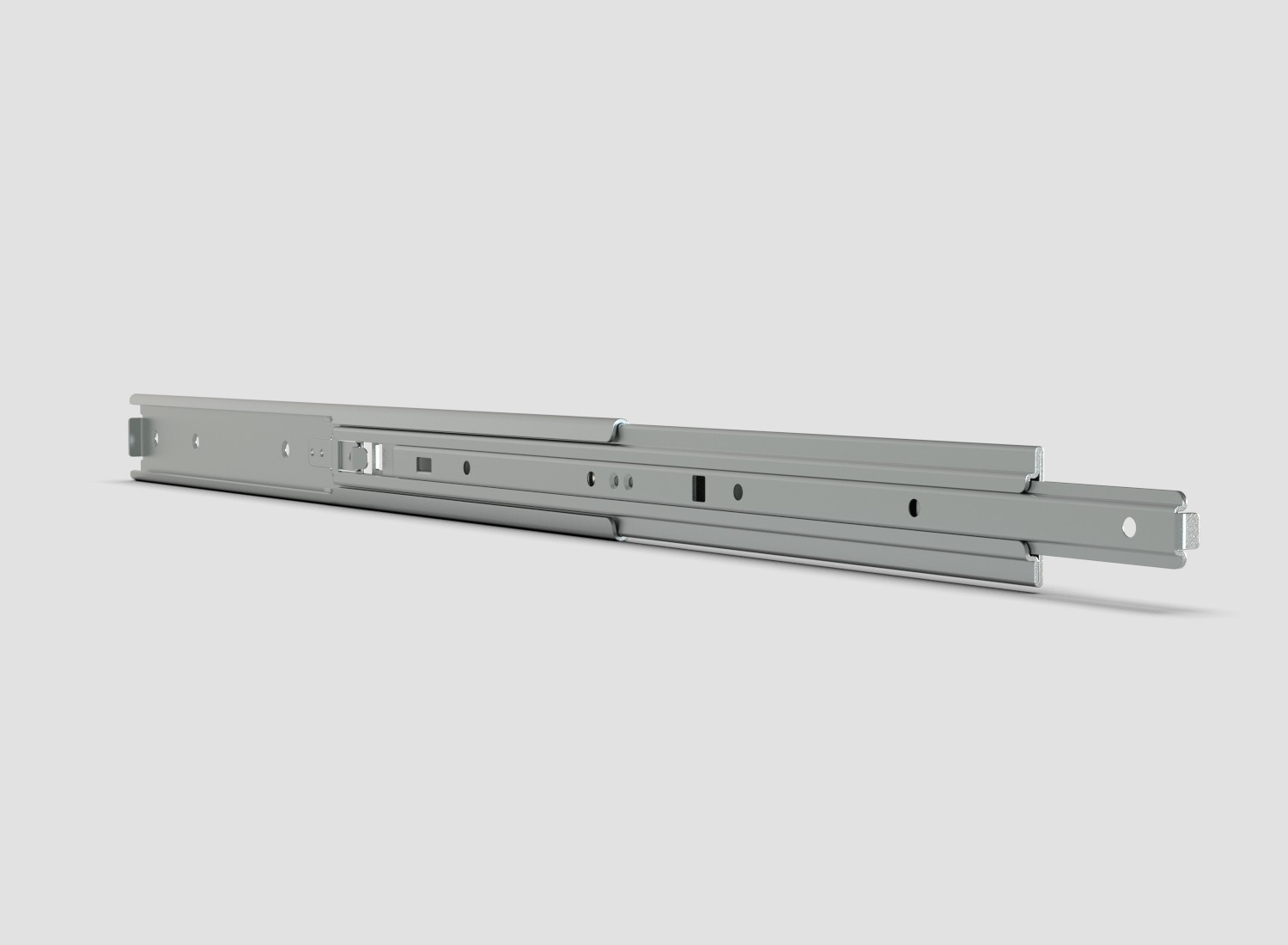

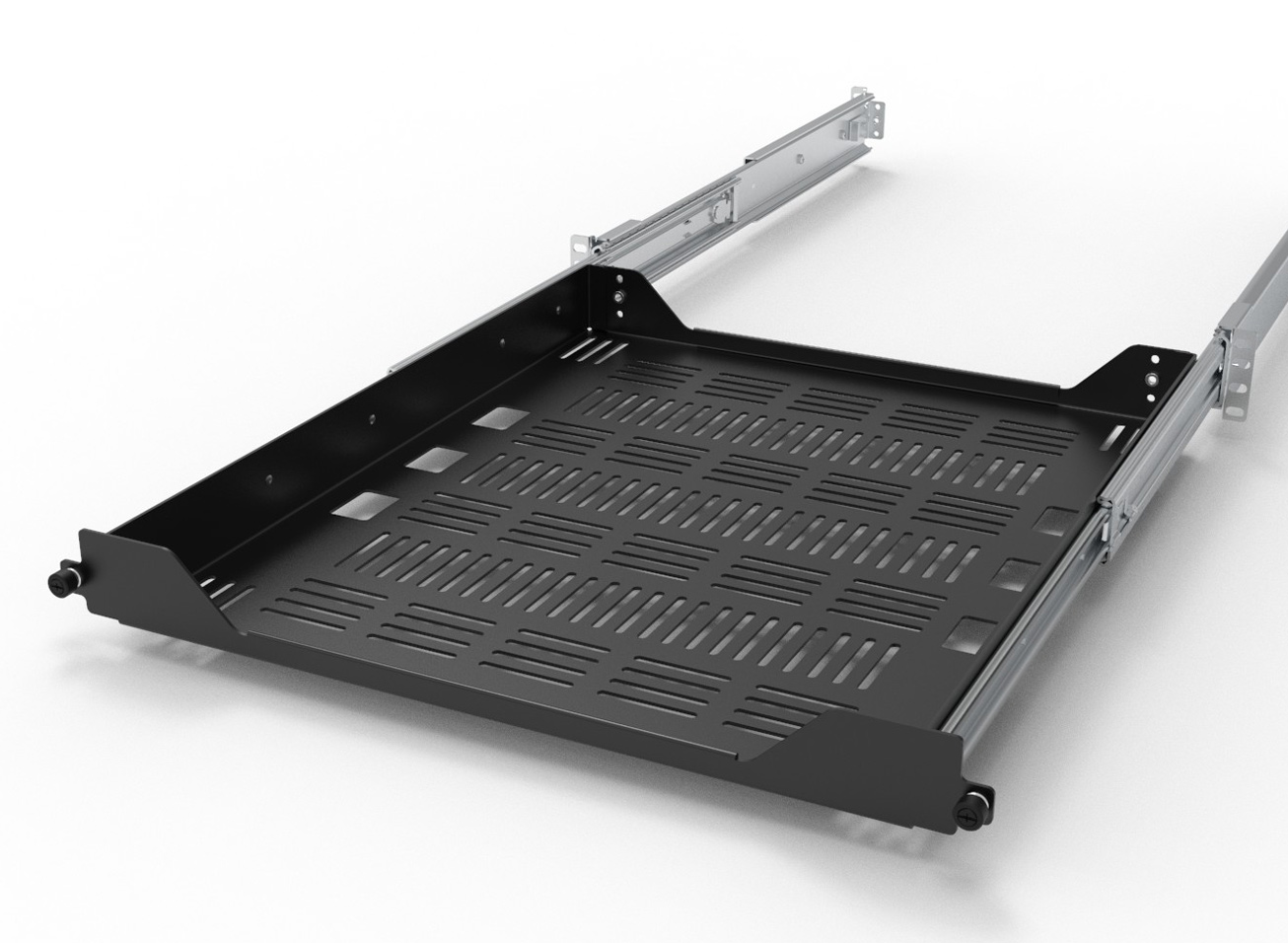

Carbon Steel Telescopic Slides

Solid bearing, ball bearing, and roller bearing slides that are available stock and completely customizable.

Learn More

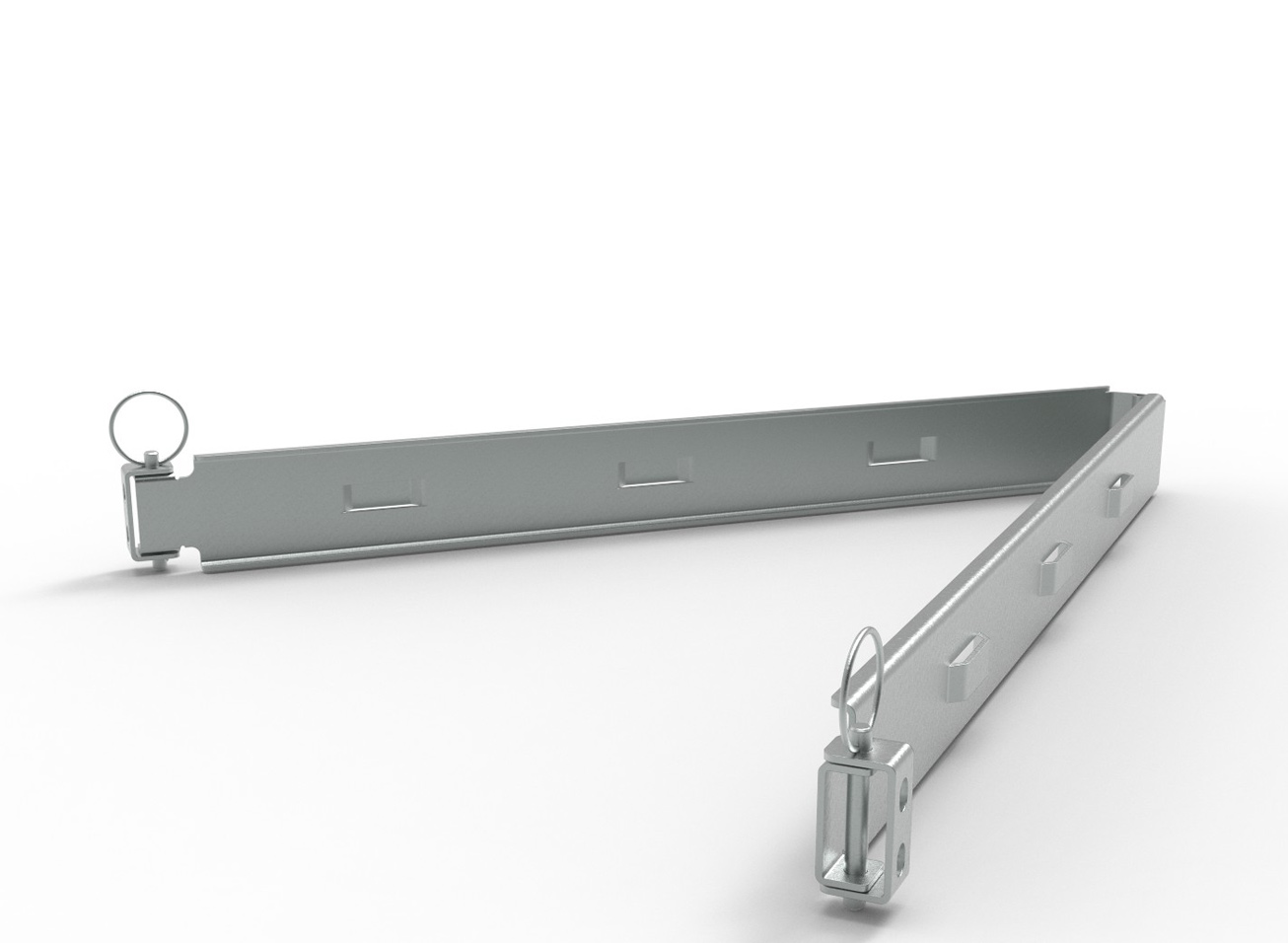

Cable Management

Cable retractors, lacing bars, and management systems for rack-mounted electronics

Learn More

Speak with a Sales Representative

Our representatives have a wealth of knowledge on all our products – let them steer you in the right direction.

Learn More